projects

contact/buy

Experiments with Investment Casting

In the interests of trying to use up some scrap aluminium I've done a few experiments with mostly metal casting, and for lack of a better idea ended up making some belt buckles.

After a brief couple experiments with sand casting I opted to do lost wax in plaster. The basic premise of lost wax casting is that a positive shape is made in wax, and connected by ducts to a funnel or such structure as to facilitate the inflow of metal and outflow of extraneous gasses and such things. After the wax structure is assembled, plaster can be cast around it, the wax can be burned or melted out, and molten metal can be added in its stead, before breaking the mould and extracting the cast.

Wax

I worked with a couple of different waxes some of which were very frustrating. Some waxes seem to have oils in them with significantly lower melting points, which when the wax is somewhat warm act to lubricate them against all other things. Parafin in particular, or perhaps just the waxes of some scented candles, seem badly afflicted by this, but as such oils are easily moved by accident it is a sort of contagious problem in a workspace.

For the most part, for main objects I ended up using something called 'green jewlers wax', a hard wax and pleasant to work with. It melts well above the boiling point of water, but setting it above a candle in a steel dish I was able to cast it into gross shapes to be carved with small hand tools, and polish it with so called odorless mineral spirits.

It is prone to splitting if cut too aggressively, and it seems better to remove small amounts at a time as with a file, but careful chisseling and slicing worked too.

I was even able to fuse peices of the green wax together with some heating and i.e. beeswax as adhesive, and drill a fine long hole with a heated needle, although it didn't come out in the cast.

Due chiefly to the aforementioned lubrication issue the greatest frustration of the wax work was in joining all the peices together. I expect this problem was worse in my case than usual because of poor choice of wax that contaminated all my tools and such, but difficult to tell.

I have seen some use of vents in such casts, but in my few experiments they did not seem essential. On the other hand the use of a deep funnel that allows for significant gravity pressure into the cast seemed very useful.

Plaster

I just used a plaster that's ostensibly for this sort of thing. It worked fine. When estimating volumes, I was once slightly fooled by the massive quantity of plaster powder, but it is better to think of the water as the true indicator of final volume than the dust.

I have seen flasks on some tutorials which have openings on both sides so the wax can be set in on the bottom and plaster poured in on top, in the opposite orientation from when metal is poured in. I just used a stainless steel drinking cup and some structure to suspend the wax in position. Sometimes due to buouncy the wax would tend to push out of the plaster, but a weight applied after pouring the cast solved this problem.

As the plaster sticks so well to the wax I tended to find the entire structure covered in plaster, this is not a major problem as its easy to scrape away later when its dry.

Placing the plaster under vacuum and agitating seemed to help remove some bubbles but its difficult to judge and some certainly persisted as you can see.

After the working time of the plaster I let it sit about 24 hours in a dry place.

Burnout and Heating

The desire here is to remove the wax from the mould, and then raise the mould to a high temperature that it shan't just freeze the metal on contact.

First I kept it in the oven upsidedown raising the temperature above the first wax, in my case parafin's, melting point. Eventually much of this wax spills out, sometimes seemingly all at once. I expect if I kept it in my oven long enough to fully reach an even temperature the green wax would melt out, however usually before this happens I have taken it out to a higher temperature electric furnace with a coiled nichrome heating element.

While watching as it heated I was somewhat alarmed to notice flames comming out of the plaster as the green wax began to burn under the heat. The flames seemed to leave a worrying amount of dark soot, but I was pleased to notice after the flame had extinguished itself that it seemed to evaporate. I let it continue heating till I figured it was fine, but given the slowness of wax spill out it was probably not too hot on the inside at the time of casting.

Metal Melting & Pouring

While the plaster was heating I began to melt the aluminium in a seperate electric furnace thing. Some of my aluminium seemed to get full of crud, perhaps aluminium oxide or other contaminants, and would not melt into a proper liquid, though it may glow red. However with good aluminium melting was easy and just a matter of waiting.

An unfortunate artefact of my setup was a difficult problem for pouring, a deep crucible with tall graphite walls tended to cool the aluminium as it approached its exit, making pours inconsistent and frustrating, as the aluminium freezes and then spills out all at once.

After pouring I'd put the mould back into the vacuum chamber and try to pull out any bubbles. Occasionally this seemed to have a major effect, as the level in the funnel would drop significantly. Before the metal seemed to all freeze I'd return it to ambient pressure and then let it cool.

Finishing

Eventually it would be cool, and knocking the mould around a bit with a hammer would bust up the plaster sufficiently to remove the cast. For the buckle pictured I also polished and filed off some of the irregularities especially as caused by the sprues. A small hole was drilled for the axis of the hinge, using a drill press. The axle itself is a peice of steel wire capped with solder, which didn't stick too well but seems to hold alright.

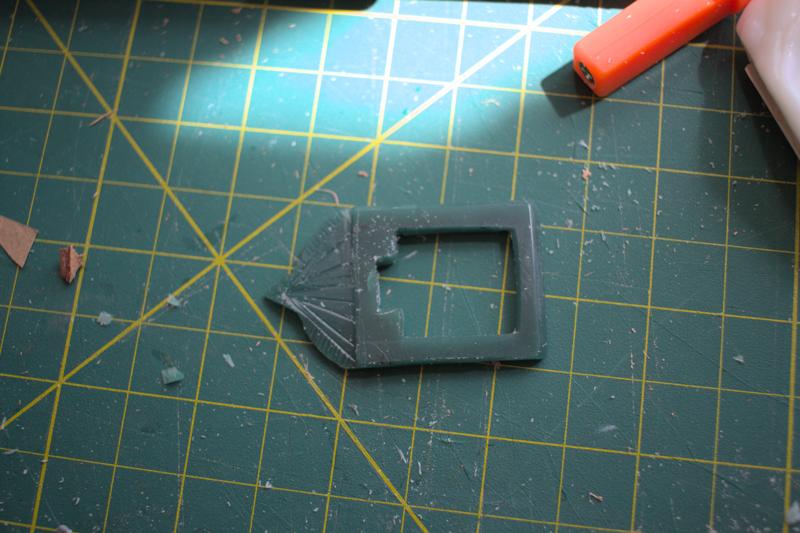

The main body of a buckle, in green jewlery wax

A buckle's components in wax, and some of the tools I was using to make it.

Assembled for casting.

A different buckle after casting and removal, you can see part of the funnel/sprue structure in the background. Small spheres of aluminium are assumed to be the results of bubbles in the plaster.

Fully assembled